An environmental Management program should be able to detecting an adverse drift in microbiological problems inside of a well timed fashion that will allow for meaningful and effective corrective actions.

There are actually stories and fears about differences in these values attained applying distinct sampling methods, media variability, and incubation temperatures. It ought to be acknowledged that, although no program is absolute, it will help in detecting adjustments, and therefore developments, in environmental high-quality. The values demonstrated in

The challenge are going to be to validate these new techniques and make certain they meet regulatory requirements even though delivering tangible Gains in terms of sterilization efficacy and operational effectiveness.

The focus of particles depends upon their diameter; consequently the bigger particles will be less in quantity as opposed to smaller particles in almost any cleanroom natural environment.

Preferably a combination of airlocks and room pressurization produce a better defense to prospective contaminants. While in the design of latest services, the process tools can be designed as the first degree defense with the product by making use of shut methods for transferring supplies from one particular container to another or from containers into the tools.

Isolator know-how is predicated to the principle of inserting Formerly sterilized parts (containers/solutions/closures) into a sterile natural environment. These elements continue being sterile over the whole processing operation, because no personnel or nonsterile components are brought to the isolator. The isolator barrier is undoubtedly an complete barrier that does not enable for interchanges among the guarded and unprotected environments. Isolators both might be physically sealed against the entry of exterior contamination or could possibly be effectively sealed by the application of ongoing overpressure.

Microbial Contaminants: Germs, fungi, and various microbes that might cause bacterial infections or spoil medication. These are typically notably concerning for sterile items like injectables.

Particulate Make any difference: Dust, fibers, and also other particles which could compromise the caliber of a drug or lessen the effectiveness of a filter or drug-shipping technique.

Considering that the most crucial source of contamination within the clean room would be the personnel, Visible documentation that may be handy in correlating output activities to contamination functions for the duration of media fills is inspired.

For the reason that USP 797 clean rooms include sterile compounding, it’s paramount to help keep contaminants out with the lab even though pharmacists and specialists prepare these medicines. To create a read more sterile environment with steady force and temperature, we perform with hospitals to realize the subsequent:

Of course, installation is readily available for the 4000 Sequence Controlled Charge Chamber. FARRAR® also provides schooling and product freezing/thawing load tests for best speed and uniformity during operation.

The inappropriate software of microbiological sampling and Assessment may possibly lead to sizeable variability as well as probable for inadvertent contamination. Sampling media and devices, and procedures indicated Within this chapter, are usually not specifications but only informational.

The design and construction of clean rooms and controlled environments are coated website in Federal Regular 209E. This conventional of air cleanliness is described by the absolute concentration of airborne particles. Solutions useful for the assignment of air classification of controlled environments and for checking of airborne particulates are included.

On the other hand, facts obtainable during the pharmaceutical industry deliver no scientific settlement on a partnership between the amount of nonviable particulates and the focus of practical microorganisms.

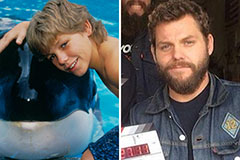

Jason J. Richter Then & Now!

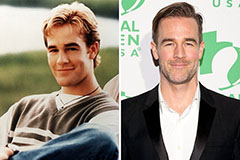

Jason J. Richter Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now!